Single Use Pressure Sensor, non-sterile, polysulfone, 1/2 inch hose barb with IP67 Connector (Standard Product)

PendoTECH

PendoTECH Single Use Pressure Sensors measure static and dynamic pressure of gases and liquids in your processes accurately and cost effectively. They are perfect for filtration and chromatography processes, monitoring of glass and disposable bioreactors, filling operations and more. They feature the PendoTECH High Accuracy Pressure (MEMS-HAPTM) chips inside. The sensors connect to monitors via an integral connector. Suitable monitors include PendoTECH PressureMAT® monitor/transmitter, a PendoTECH Process Control System, or other pre-qualified third party monitors. They can be non-invasively tested in-place with the PendoTECH PressureCHECKERTM. They are the alternative low-cost solution for use with tubing to the existing stainless steel pressure transducers on the market.

Feature and Benefits:

• Available in 1/8 to 1 inch hose-barb connections, sanitary flange & luer connections

• May be repeatedly cleaned and re-used

• Operating range from -11.5 to 75 psi (-0.79 to 5.2 bar)

• Accuracy claim from -10 to 60 psi (-0.69 to 4.14 bar)

• Unobstructed flow path & no dead legs provide dramatically reduced hold-up volume versus stainless steel transducers or gauges

• 100% tested for critcal quality attributes during manufacturing

• Available in polycarbonate or caustic resistant polysulfone materials of construction

• All fluid path materials meet USP Class VI requirements both pre & post irradiation

• Certificate of Quality included with lot certification; individual NIST Certificates are optional

• Manufactured in a ISO 9001 certified facility; ISO Class 7 clean room

• Compatible with gamma irradiation and X-ray irradiation

• May be non-invasively tested in-place via test port

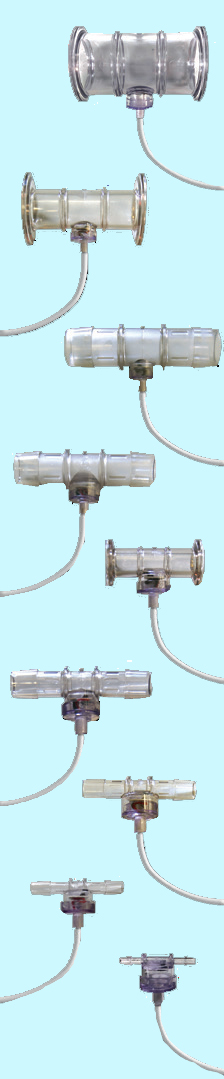

Hose Barb & Sanitary Flange Sensors

The hose-barb sensors securely adapt to process tubing. Their design imparts no obstruction on the fluid path that can cause a pressure drop and there is no dead-leg at the point where the pressure is measured. The hose-barb design features no mold parting-line where the tubing is secured, which can be a source of leaks. The single barb design provides space for the hose to relax behind the barb, causing the tie-wrap to work like a drawstring. Anti-rotation ribs lock the tubing, preventing it from loosening from a twisting motion. The sanitary flange sensors come in a variety of sizes and meet the ASME standard. The hybrid flange to barb sensors create a convenient transition from tubing to devices with sanitary flanges such as filters. They may even eliminate the need for costly adaptors and clamps.

Luer Sensors

The luer sensors have male/female luer lock inlet/outlet ports and come with a cap on the female luer port for dead-end applications. With the universal luer fitting, they can be adapted to processes in different manners. The polycarbonate version is available sterile which is convenient for certain processes. They can be aseptically connected to a bioreactor to monitor vessel pressure. Testing has indicated that accurate process pressure readings are obtained in tee configurations. They can also be connected directly to the vent port on some filters.

Pressure Sensors With Water-tight IP-67 Connector

All sensors available with water-tight panel-mount connector (versus standard molded connector) for OEM applications. The standard molded connector is IP67 when connected to reusable cable.

Serialized Sensors with Individual NIST Certificates

Depending on the implementation of the sensors and end-users preferences, documented values of a sensor reading across a range of applied pressures may be desired. As a product option, select part numbers are available with a serial number in addition to the lot number along with a NIST Certificate report for each sensor with the NIST traceable reference used. Part numbers listed with suffix identifiers ( B, -30, or -60) added to the part number include individual NIST Certificates. While every sensor undergoes the standard acceptance test to meet lot requirements, these serialized sensors have additional testing and documentation of the actual readings at each applied pressure. The applied pressures and readings on the NIST certificate are based on the range of testing required. Available NIST Cert products (part # suffix): – B is for low pressure applications such as a bioreactor and the certificate is in the range of 0 to 6psi Values on NIST Certificate (in psi): 0, 1, 2, 3, 4, 5, 6, 0 – 30 is for moderate pressure applications in the range of 0 to 30psi Values on NIST Certificate (in psi): 0, 5, 10, 15, 20, 25, 30, 0 – 60 is for higher pressure applications where the PressureMAT products are used and the certificate is in the range of 0 to 60psi. Values on NIST Certificate (in psi): 0, 10, 20, 30, 40, 50, 60, 0

SKU:PREPS-N-050-W

PACK SIZE:1

CATEGORIESs: Fluid Handling